Introduction

In the current fast-paced world of business Supply chain predictive analytics has become much more difficult than it ever was. From planning demand for the future to the management of inventory as well as the logistics of delivery, there’s amount to be dealt with. As businesses try to improve their processes and efficiency, a tool is emerging as an innovator – supply chain predictive Analytics. This unique approach is a combination of past data, machine learning, and mathematical modeling to forecast the future events in supply chains with incredible efficiency.

If you’re a business looking to lower expenses, increase delivery time, and improve satisfaction with customers, Predictive analytics has the possibility of revolutionizing processes. In this post, we’ll look at the significance of predictive analytics within supply chains, its benefits, examples from real-life situations, and ways to implement it in your company.

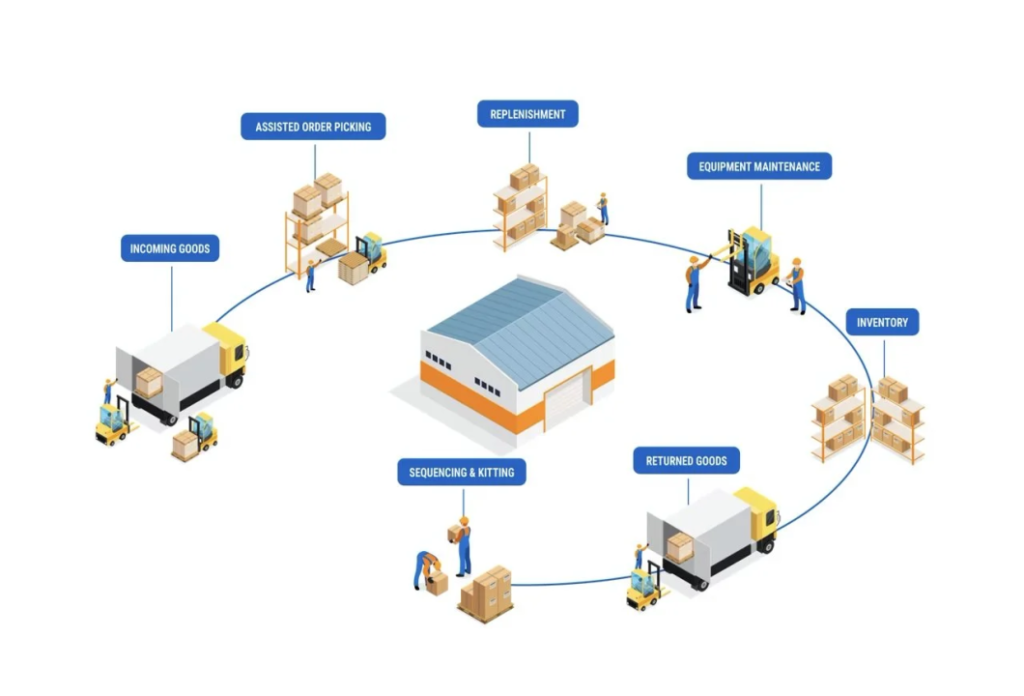

Problem: The Challenges in Supply Chain Management

Supply chains have been vital to the business’s success, But numerous issues strike the modern supply chain. They face unpredictable fluctuations in demand and disruptions due to worldwide events, inefficiencies as well as poor management of inventory. Based on a study by the Institute for Supply Management, 79% of businesses suffer disruptions to their supply chains because of various reasons like natural disasters or geopolitical issues, along with the failure of suppliers.

Traditional supply chain processes are heavily based on the human ear, which can result in mistakes. For instance, forecasting the demand with basic historical data could miss seasonal patterns or changes in global markets. This means that businesses are faced with stock shortages, overstocking, delays in deliveries, and, eventually, loss of revenue.

How Can Predictive Analytics Help?

That’s the point at which Predictive Analytics steps in. It employs advanced algorithms and data models to anticipate new trends and make the management of the supply chain more intelligent and more efficient. Through the use of data from many sources — sales history, patterns in the market, consumer behaviour as well as weather patterns, predictive analytics provide precise forecasts to help companies make more informed decisions.

Agitate: The Costs of Inefficiency

The consequences of inefficiency within the supply chain extend past lost opportunities. In the event of disruptions and poor management, it may result in massive loss of money, damage to reputations of companies as well as a decline in the trust of customers. When companies are overstocked with products, they don’t have to pay for storage fees, but they also however, they run the risk of making their products outdated. In contrast overstocking may result in lost sales opportunities as well as dissatisfied customers.

Take the auto industry, for example. In the event of a delay in delivery of parts, it will stop production, which can lead to costly downtime and miss deadlines. An analysis conducted by Deloitte discovered an average of 79% of companies think that predictive analytics can aid in reducing cost by 20 20%. In the industries where efficiency is an problem, the cost is shockingly excessive. However, using predictive analytics is an effective solution to minimize the chance of being a victim.

Solution: How Predictive Analytics Can Transform Supply Chains

Predictive analytics give businesses the chance to identify difficulties in the supply chain prior to their time and being able to make the appropriate decisions ahead of time before problems occur

Through the analysis of historical data as well as using machine-learning models companies can predict the demand for their products, improve the amount of inventory, and prepare for the possibility of disruptions to supply chain operations in the future.

Let’s take a look at a few important areas in which predictive analytics has made huge strides:

Demand Forecasting

Predictive analytics enables firms to anticipate demands more precisely by analysing patterns and trends that have been observed in past sales, customer behavior as well as market conditions. In particular, retailers are able to forecast the demand for certain merchandise during certain months, holidays, or sales. This can help businesses plan their business better prevent overstocking as well as reduce the risk of stock shortages.

Inventory Management

The proper management of inventory is vital to ensure that businesses can meet consumer needs while also reducing storage expenses. Analytics that predict the future help businesses maintain an optimal level of inventory by predicting the future needs of products by using models for forecasting demand. The company can eliminate surplus inventory and reduce any costs that come with stocking up.

Risk Management

Supply chains are subject to numerous dangers, such as delays for transport providers problems or tensions in the geopolitical arena.

The use of predictive analytics helps to identify risks that could be a threat and offer alerts in advance, which allows businesses to take preventative actions. As an example, companies are able to use data on weather conditions to predict interruptions to shipping operations or locate alternatives to suppliers prior to issues arising.

Supplier Performance Monitoring

Predictive analytics also helps companies evaluate the effectiveness and performance of suppliers. By analyzing the data of the past regarding time to delivery in addition to high-quality and reliability, firms are able to predict problems in advance and make changes to suppliers before they necessity to make sure they will have the same supply of materials and goods.

Route Optimization

In the field of logistics Predictive analytics are able to optimize the delivery route, thus reducing transport expenses and speeding delivery. When analyzing variables such as the weather, traffic patterns and shipping data, organizations are able to ensure delivery on time as well as reduce the use of fuel and transport costs.

Customer Behavior Analysis

Predictive analytics aren’t just about planning supply chain requirements, but it’s also concerned with understanding the behavior of customers. Through analyzing patterns of purchase as well as customer preferences and their feedback, companies can modify their supply chain in order in order to satisfy customer demands more efficiently.

Real-World Case Study: How Predictive Analytics is Driving Success

An excellent example of the use of predictive analytics is Walmart, which is one of the largest retail stores in the world. Walmart is able to implement predictive analytics in order to improve the supply chain of its business, while reducing wasted inventory and improving its management of it.

In the year 2015, Walmart began using advanced data analytics in order to forecast the fluctuations in demand and alter its inventory to meet these changes. In the end, Walmart decreased out-of-stock products by 10 percent, which dramatically improved sales as well as customer satisfaction. Walmart also made savings of millions of dollars through reducing excess inventory and improving the stock levels of the warehouses.

A different example is UPS, which utilizes predictive analytics to optimize routes. Based on the analysis of conditions like weather, traffic patterns, and the volume of packages, UPS can reroute deliveries at a moment’s notice, making sure of timely delivery and saving on fuel. Predictive analytics actually has helped UPS decrease its fuel use by 10 million gallons a year which translates into substantial savings in costs and lower carbon footprint.

My Thoughts on Predictive Analytics in Supply Chains

I am convinced that predictive analytics isn’t just a “nice-to-have” tool but an essential tool for any business trying to compete in the current marketplace. I’ve seen firsthand the power technology has. Technology can bring to detect and fix problems before they become too out of control. By using information and advanced algorithms firms can make better well-informed decisions, save money and improve customer satisfaction.

One of the most important benefits of predictive analytics is the capability to help companies in turning data into actionable information. In the past, it was difficult to make use of data and unused, but with the capabilities of machine learning and AI, businesses are able to effectively harness the power of data to make better, more efficient choices. I’m eager to see the way this Technology is constantly evolving and will affect the future of supply chain management.

Implementing Predictive Analytics in Your Business

If you’re interested in integrating predictive analytics into the business, there are a few tips to help you get started:

- Review Your Data Presently Assess the information you have. Do you have enough historical information to be able to predict future events? Are there holes in your records that have to be closed?

- Put money into Technology and invest in appropriate tools and Technology that can manage the use of predictive analytics. It could be machine learning software as well as data visualization tools or cloud-based platforms.

- Start small In case you’re not familiar with predictive analytics, begin using it in only one aspect of your supply chain, like planning inventory or forecasting demand. When you’ve seen good results, you can expand your application to different sectors.

- Monitoring and adjusting: Models which predict need tweaking in the course of time. Make sure you regularly test the accuracy of your model and modify it as necessary.

- collaboration with experts Be sure to contact experts in the domain of data science or supply chain experts who can help you understand the data to improve the model you have created.

Conclusion: The Future of Supply Chain Management

Predictive analytics have transformed the management of supply chains from an active process into an active one. With accurate forecasting of the demand, maximizing routes as well as reducing the likelihood of failure, firms are able to increase efficiency, reduce costs and improve the experience of their customers.

As we advance in Technology and the advancement of technology, the analytical field of predictive analytics will grow and provide more insights on the effectiveness of the supply chains.

If you’re not doing so then now is the best right time to take advantage of predictive analytics to remain ahead of the pack. Future supply chain management technology is now here and driven by information.

FAQS

What exactly is supply chain predictive analytics?

Predictive analytics for the supply chain involves the application of data from historical sources as well as statistical models, as well as machine-learning algorithms to anticipate future events within the supply chain, including demands, requirements for inventory, and the possibility of interruptions. Businesses can make informed choices to improve their operations.

What can predictive analytics do to improve demand forecasting?

Predictive analytics can improve forecasting for demand through the analysis of sales history as well as market trends and external influences (like the weather or holiday dates) to forecast the demand of the future with more accuracy. It reduces the chance of inventory shortages or excess stocking.

What’s the primary advantages of utilizing predictive analysis for logistical supply chain management ?

These benefits include better forecasting of demand as well as optimized inventory management. Less disruptions to supply chains and improved customer satisfaction as well as cost savings from improved distribution of resources.

Are predictive analytics able to help in reducing supply chain risk?

Predictive analytics can help to identify risks before they become serious by analyzing data relating to the performance of suppliers, problems with transportation, and other world incidents. Businesses can take preventive measures, like locating alternative suppliers or altering delivery times.

What sectors can most benefit from predictive analytics in the supply chain?

Retail manufacturing, automotive, and logistics are among the most beneficial. Every industry that is heavily dependent on supply chains to manage production management, inventory management, and delivery could see significant improvement with predictive analytics.

What is the accuracy of forecasts made by predictive analytics?

The reliability of forecasts depends on the amount and quality of data utilized as well as the algorithms used and the degree to which the algorithm is honed. Even though no algorithm is completely accurate, predictive analytics are able to provide highly accurate forecasts that drastically reduce uncertainty within your supply chain.

What can predictive analytics do to help to manage inventory?

Predictive analytics can help companies maintain an optimal level of inventory by forecasting future demand and changing the stock levels to meet demand. This lowers the cost of storage and decreases the possibility that you will run out of stock or have surplus inventory.

What technologies are needed to enable predictive analytics within supply chain management?

For the implementation of predictive analytics, firms require equipment such as machine learning applications, data analytics platforms, and cloud computing systems, as well as data visualization software for processing and analyzing huge amounts of data effectively.

Are predictive analytics just for the largest businesses?

Larger companies may have greater funds to invest in the latest analytical tools, and smaller or medium-sized enterprises can profit from the benefits of predictive analytics. It’s cost-effective and includes tools which are able to be utilized by all businesses, regardless of size making the technology available to all kinds of.

How does a business begin to implement predictive analytics within the supply chain?

An organization can begin by analyzing the data it has, acquiring the appropriate tools, and applying models that predict the future to particular areas of its supply chain, such as the forecasting of demand and risk management. Additionally, it is beneficial to partner with experts on data to assist in the development process and tweak models with time.